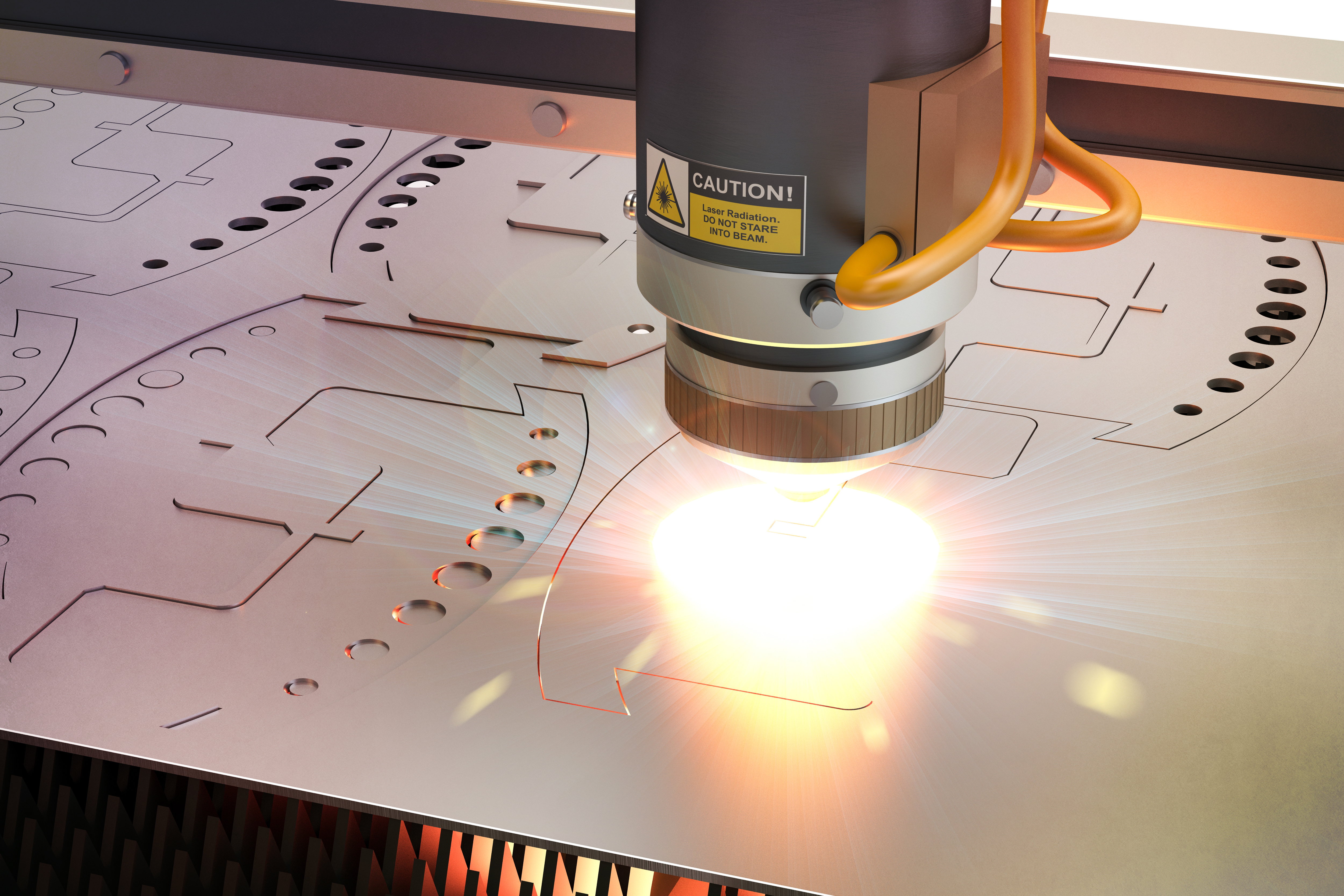

Laser engraving is a sophisticated process that requires the use of the best laser engraving software to achieve the desired result. In general, there is a laser beam that moves across the surface to create different designs.

To produce unique laser engravings, you need to use a special engraving machine that is controlled with laser engraver software. There are very few such programs that are available free of charge, but we managed to select several worthy options.

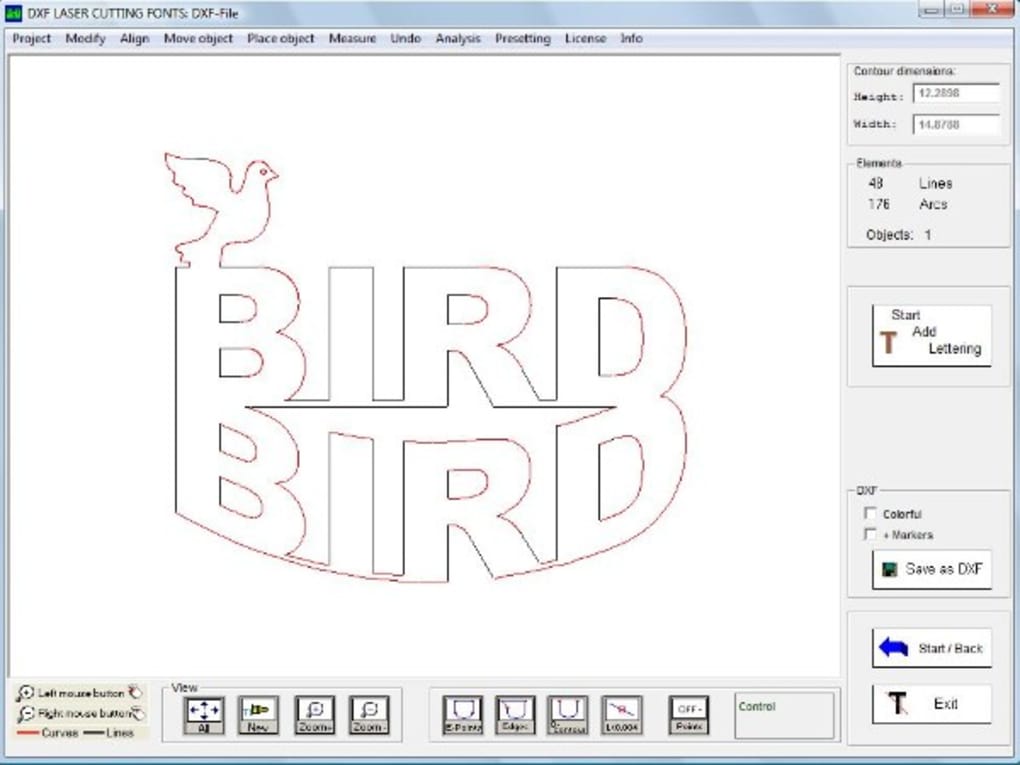

These programs include text, graphic design and layout, photo editing, CAD/engineering design, and serialization and coding software. Here is a list of some of the more common software programs used with laser systems (also known as laser cutters, laser engravers, or laser machines). LaserCAD Cutting System, Free Download by Wei-Hsin Computer-Tech Ltd. Multi-Format Laser Cutting File. Library laser the best page to download free designs Free DXF files (AutoCAD DXF), Free Vectors Coreldraw (.cdr) Files Download, Designs, Patterns, 3D Puzzle, Silhouettes, Vector Art for CNC routers, laser cnc, plasma cutter. Download and View in dxf file viewer. LaserGRBL is a free laser engraving software for Windows. Through this software, you quickly engrave predefined designs. To import predefined designed, you can use its Open File option that supports GCODE file, Raster Images (JPG, PNG, BMP, etc.), and Vector Images (SVG, EPS, etc.). As soon as you load design in it, you can view its engraving pattern on the main interface of this software.

Top 5 Laser Engraving Software

- LaserWeb4 - Controlling your laser cutter based on your design

- Inkscape - Scalable vector is its native format

- LightBurn - Importing of all common vector graphic

- TurboCAD - With features to laser cut easier

- OnShape - For tablets and smartphones

In this review, we have described the best programs for laser cutting, which you can also rely on to create vector files. Very few tools are initially aimed at laser cutting, but they are irreproachable when it comes to creating precise vector graphics that can be further used in laser cutting projects.

1. LaserWeb4 - Our Choice

- Translates vector file to your laser cutter

- Import multiple files into a single project

- Great for collaboration

- None

Verdict: LaserWeb4 is the premier software of digital laser engraving services. This type of software uses the same technology that is found in an industrial laser engraving machine; the difference being that this software is designed to be used on a desktop PC rather than a laser printer.

The main pros and cons of the software can be boiled down to three major factors including price, user friendliness, and functionality.

2. Inkscape

- Compatible with many different formats

- Free open source easy to use

- Can work as converter

- Lag with large files

Verdict: Inkscape is an excellent tool for creating images with the FABOLIFT laser engraver and it has amazing software for editing. The pros are that it is very fast, it allows for high quality conversions to almost any format and also that it can be used as a graphic design application as well.

The cons are that it is not compatible with some formats like psd as it uses bitmaps which are only accepted by the Adobe format library. So if you are looking for an affordable option to create professional looking laser engraved pictures then Inkscape is not the best option.

3. LightBurn

- Great community web page

- Easiest program to engrave

- Customer service is exceptional

- Free trial

- Pricey after trial

Verdict: LightBurn is design, modification, and interactive software for the laser cutter. With LightBurn you could do: import images in various popular image and graphic formats (like AI, EPS, PDF, JPEG, DXF, PNG, JPG, GIF, BMP) into the laser engraving software for a more accurate result.

You can also tweak settings in many different ways. These features of LightBurn make it a must-have for every laser engraving business.

4. TurboCAD

- Relatively easy to use

- Works as an exporter

- Produces accurate drawings to scale

- Rendering is not standardized

Verdict: TurboCAD is an award-winning CAD software program for full-scale product design and drafting that runs on Microsoft Windows and Macintosh operating systems. The product is used by architectural and engineering firms worldwide for designing and rendering complex structures and products, such as buildings, bridges, automobiles, and even bridges and monuments.

5. OnShape

- No need for installation

- Runs on cloud platform

- Allows users to create error-free 3D printing files

- Very easy to pick up and deploy

- Interface may be a little clunky

Verdict: OnShape is a simple, computer-aided 3D design tool, delivered over the Internet through a Software as a Service (SaaS) model. This cutting-edge creation tool will make it possible for small and medium-sized companies to create high-quality design drawings from their computer desktops.

OnShape has a number of advantages over traditional drafting tools and software. The tools are easy-to-use and the company guarantees that the end product will meet or exceed the expectations of the customer.

In this article we will design 3D objects for laser cutting using the free and open source CAD software FreeCAD. We will create a simple mounting bracket as an example.

These mounting brackets are designed to hold the cooling unit of the K40 that we build here. This is a bit too complicated to model as a simple 2d model in Inkscape as we have shown

in this article

FreeCAD however is easily able to handle this design.

Enable laser cutting CAD in FreeCAD

The LC Interlocking Workbench is a great way to design even quite complicated shapes for the laser cutter. Install the workbench following the instructions on the website.

In FreeCAD we switch to the LC Interlocking workbench.

Designing the shape with the laser cut interlocking workbench

We want the mounts to have a length of 150 mm and the short sides to be around 25 mm wide. The box design tool from the workbench gives us a head start and creates the necessary pieces easily.

Free Cad Software

We just fill in the width, height, length of the box and the the thickness of the material – which is 3.1 millimeter – and get a box of that size.

We delete the two sides that we don’t need with the delete key and position the two sides that later will become supporting elements 30 mm inwards.

To move objects by a set amount we add the respective number in the positioning area. Just type the plus sign and the number and let FreeCAD do the math for you.

We then select all the pieces and click on the button to create connection tabs. In the task panel we add all parts to the assembly with the add same parts button. By pressing space we hide one long piece and mark the faces of two short pieces so that they get tabs.

While for the short sides the default setting of a single tab works fine we increase the amount of tabs for the long sides to five.

After hiding the second long side we can add the other two faces and after closing the task panel all the tabs are created.

Refinement with the parts design workbench

Now we switch back to the part design workbench to modify the pieces. Before we can modify a shape we have to convert it into a body with the button showing a blue staircase.

For the smaller pieces we create a sketch on their surface and then use the button with the blue box to get the corners of the shape as a reference.

With the multiline tool we then draw a triangle and directly close the sketch.

By pocketing the triangle through the entire structure we cut away part of the shape. This change is purely for the look.

We repeat the same steps for the other supporting structure.

The two long pieces get holes to mount the cooling unit and screw the mount to the cart. These are also sketches on the surface that are then pocketed through the piece.

Creating sketches in FreeCAD follows a simple logic. If you get close to an existing point and it turns yellow the point is catched and a constraint is automatically created.

Now the circle still has an arbitrary size. We select the circle and add a constraint to make its radius 2mm. We close the sketch and pocket the hole though all the material.

On the other piece we first create two circles that have an arbitrary size and position. Then we constrain them.

In a first step we mark both centers and make sure they are on the same height with a horizontal constraint.

When selecting both circles the radius constraint is automatically applied to both elements. We measured the distance of the mounting holes of the radiator to be 120 mm – which is a horizontal distance constraint.

Laser Cad software, free download Crack

We then again use the blue box icon to get the edge of the shape as a reference so that we can measure the horizontal distance of 7,5 mm and the vertical distance of 10 mm.

After closing the sketch we selet pocket and go though all the material. We finish the shape and can inspect it from all sides.

Laser cutting

In order to cut them on the laser we select all the parts and go back to the LC Interlocking workbench. A very cool feature is this button with the small squared that puts all pieces flat in one plane.

Lasercad

We export these shapes to a DXF file and can cut them on the K40.

After that we cut the parts out the mounting brackets are ready for glue up.